High-Performance Solutions for Turning Centers Deliver Exceptional Results

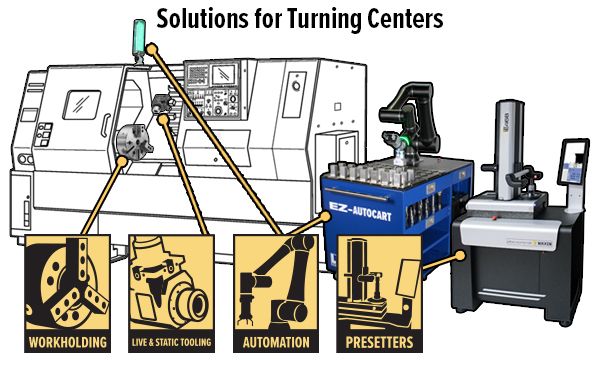

For any machine shop, investing in a turning center is an important decision. In addition to the capital equipment, turning center accessories are an equally significant decision. Reason being is they directly impact machining results by influencing cutting performance, workpiece stability, coolant delivery, and overall machining dynamics. So, investing in high-performance turning center accessories and automation as well as optimizing their selection and usage is essential for machining accurate parts, maximizing productivity, and gaining a competitive edge in the market.

When seeking machine tool accessories for turning centers, manufacturers face a range of challenges:

- Compatibility: Ensuring that accessories are compatible with specific turning center models can be challenging. Manufacturers need live and static tools that integrate seamlessly with their equipment without requiring extensive modifications.

- Quality, Performance, and Efficiency: Accessories must meet high-quality standards to withstand the demands of turning operations. Manufacturers seek accessories that deliver consistent performance, durability, precision and maximization of turning center time. When it comes to efficiency, tool presetters help to minimize machine downtime to help increase the efficiency of a machine shop.

- Versatility: Turning applications can vary widely, requiring accessories that can accommodate different materials, part geometries, and machining requirements. Manufacturers need versatile workholding such as power chucks and quick change flex chucks (QCFC) that can adapt to changing production needs.

- Innovative Technology: Manufacturers look for turning center solutions that incorporate the latest advancements in innovative technology to improve productivity, efficiency, and performance. With the lack of skilled workers being an issue in manufacturing, machine shops value cost efficient automation solutions in order to thrive in today’s challenging manufacturing landscape.

- Technical Service and Support: Manufacturers rely on technical service and support to seamlessly integrate and maintain turning center accessories. Being proactive about service can mitigate machine downtime, maintain precision, increase productivity, prolong equipment lifespan, and circumvent last minute high costs.

Videos: Why Manufacturers Choose Lyndex-Nikken Solutions for Turning Centers

Hear and see for yourself how Lyndex-Nikken quality turning center accessories provides optimal machining solutions for: